It's rollercoaster season again! If you're around MIT campus this week, the 2017 coaster will be up and running (should be completed tonight, actually!)

So with that, and me being laid up in bed with a busted knee... I should hurry up and do a construction post about the 2015 rollercoaster! (only two years delayed........)

|

| Digging holes for a cinderblock/pier block foundation |

East Campus has the best back-to-school traditions. Freshman at MIT get to pick which dorms they want to live in, and each dorm has its own character it wants to show off. At East Campus?

"We're cool people! Build cool things with us!"

So that's where the tradition of building large wooden structures comes from. The upperclassmen come back at the end of summer, set down luggages, and immediately get to work. From groundbreaking (above) to wiring lights and putting together a DJ set, all time and effort is devoted to making a student-led, student-made hell of a dance party (the coaster, the fort, all of it is ostensibly for this dance party)... all within around 10 days! Then everyone admires the fruits of their efforts for around another week, and then the following weekend it all gets deconstructed before classes start.

The story of an East Campus rollercoaster, of course, begins way before construction starts. In January, about 7months before, several enterprising groups of students propose projects they want to lead. Sometimes these include a rollercoaster (~2005-2008; 2014-2015; 2017), almost always they include a wooden fort, sometimes they're mildly different. The student chairs in charge of organizing REX (the back-to-school-event), select projects to fit a budget and get to work planning logistics and fundraising. The project leaders get to work too.

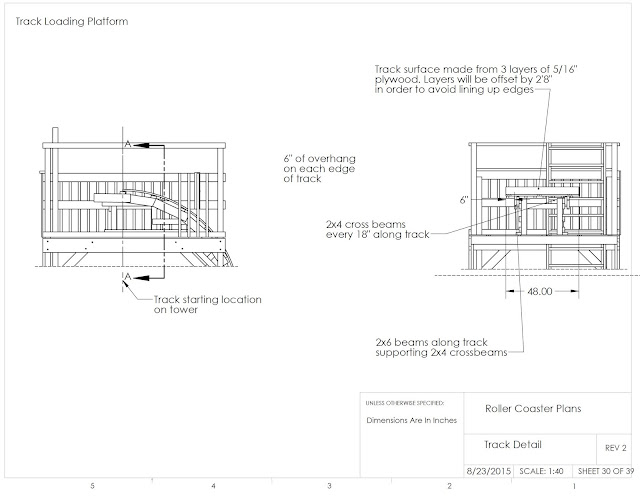

There's drawings and models and acceleration simulations to be made, and a whole bunch of math. Luckily most of the structural calculations can take advantage of years of tradition with previous wooden projects. The few novel calculations for the 2015 coaster were to figure out how to safely handle a 90deg drop (safety both with regards to acceptable G-forces on the rider and structural loading on the track)

|

| Some examples of the structural calculations |

By the end of spring, the designs are done and drawings are ready to send off. Rollercoasters have to get approval from MIT EHS, a structural engineering PE, an architect, Cambridge Fire Dept, and City of Cambridge (it's classified as a temporary building). The REX chairs do a fantastic job of organizing the meetings and getting everyone convinced; over the summer they and the project leads get to sit in a ton of meetings.

Anyway once the designs and BOMs are finalized, safety plans and assembly instructions (think lego manuals) get written up, and everyone gets hyped for rush to start!

The loading tower is the first structure to go up. Its placement determines the location and orientation of the rest of the rollercoaster, and it also requires the highest concentration of manpower.

The 2014 and 2015 towers were attached to the fort. The 2017 coaster tower is separate.

|

| Starting to install 3rd floor spandrels |

|

| First things to go up on every floor are temporary safety railings. |

Once the third storey of the tower is done, then it's time to attach all of the frames. These frames were created while the project leads focused on the tower - they're good things to delegate and use to teach freshmen how to use power tools.

|

| A representative frame's construction sheet |

|

| Locations of each frame |

|

| Frame Assembly |

|

| Putting track sections on the vertical drop. |

|

| Instruction sheet for a track section |

Once the rough curvature of the rollercoaster is established, multiple layers of plywood are tacked on to form the track. Other notable features of the rollercoaster include the work platforms that are not only useful during construction but also make safely dragging the cart back possible.

|

| Adding vertical supports to the track units. |

And that's the coaster! There's a good construction timelapse video of the fort and rollercoaster below.

(video credit: Banti Gheneti)

You might be wondering about the cart. The cart is an ridiculously-heavy wood and aluminum-plate contraption bolted to a bucket seat (5-point harness!)

I didn't have any pictures of it from REX, but I did take some afterwards when it was in storage.

The 2015 cart has a total of 8 wheels rolling on top of the track, along with 4 wheels beneath (to prevent the cart from flying off) and 4 on the outer edge (preventing skidding). The side wheels received extra abrasion protection via heat-shrunk soda bottles (a MITERS tradition).

The cart clears the steep track curvature by having a bent frame, ~10deg total.

So what made this rollercoaster different from the previous year's? Not much, except for the vertical drop. How vertical is vertical?

|

| Art credit: Emily Tencate |

|

| http://www.ultimaterollercoaster.com/coasters/records/wood-roller-coasters.php |

We set out to beat this record and make a true vertical drop. And we did!

|

| Technically beat a world record! (Steepest Drop, Wooden Rollercoaster) |

We reached out to Guiness world records, but they didn't make it over in time for deconstruction. Oh well.