For this assignment, we were told to go forth and create a linear motion axis built from scrap and then measure its precision. I had some leftover 8mm steel rod from what used to be 3D-printer materials, so I decided to make a small linear rail out of that. These rods were only 30cm long and rather thin for desk material, so I'm treating this one more like a scale model. I can use this to see what I can improve for the real thing.

With round straight steel rod as my rails, I have two main concerns to address:

- Fabricate rail holders to maximize parallelism of the rods

- Make a carriage to achieve best slidey-ness/load capacity with least effort/wobbliness

The rail holder objective is fairly straightforward, but the carriage requires some thought. Generally the more constrained you make a slider, the less load capacity it gets (before you get friction problems)

I decided to see how far I could get with a circular-bore carriage (slider on one rail has cylindrical bores, and the other rail just has a flat.) Fundamental failure modes of this design will be angular wobbliness in the xy-plane (parallel to the base, but would move a laser beam side to side), since a slip-fit circular bore inherently will allow side-side play. However, such a design would prevent the carriage from lifting off the rail and I could later reduce angular errors with a preloading mechanism. Also, this design is really easy to machine.

Below is some scratchwork:

So if I have an 8mm rod, and I have a clearance bore of 21/64" (closest common machine tool size, equal to 8.335mm), what's the best error I can theoretically achieve? More fun scratchwork below:

|

| I can expect between 0.2° and 0.6° angular error assuming my carriage connection is actually rigid |

I needed to predict what sort of errors I would see from this device; for that I used another Slocum spreadsheet. This error apprortionment spreadsheet explores allowable errors for all the components in a machine based on total error the engineer wants to achieve and how precise the engineer can expect to get each individual part.

The logic here is that I can easily acquire a decent actuator and build a decent structure through clever machining processes, but my sliding axis idea is going to rely on flawed delrin bearings and a really derpily-mounted and honestly not well-collimated laser "sensor". So I expect the most error to come from these items. The goal is to achieve 0.5mm precision (arbitrarily lofty goal) despite these items - for that to happen, my linear axis needs to have 0.33mm precision (angular precision 0.09deg) before considering load. (I'm moving things on this axis too slowly to care about thermal or process errors.) Welp, here goes.

I machined a block of delrin to create the four rail holders and the circular-bore carriage sliders. All the critical features of the rail holders (height, bore, and mounting bolt holes) were machined first, subsequently the block was bandsawed into four pieces. The slider pieces were also matched by machining everything before splitting, to improve relative precision of the components during assembly.

|

| Bottom faces of rail holders and slider (left) and top faces (right) |

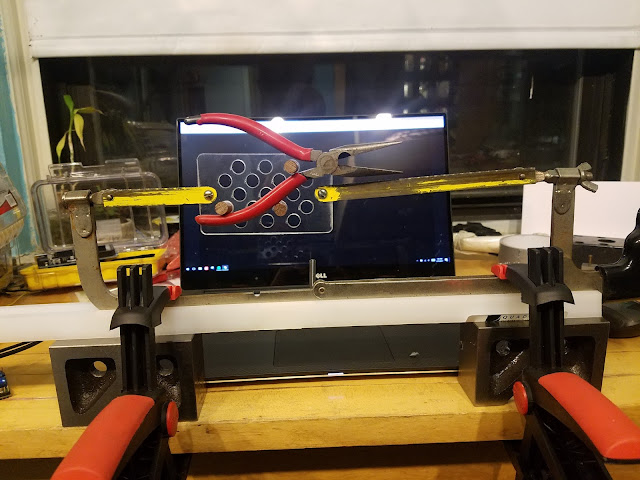

After assembling the more constrained rail, I measured the distance from the top of the rod to the slider - 1.42mm, and found a scrap piece of acrylic for the flat that reasonably matched that height. I then bolted my simple linear rail assembly to my lab's optical table, then attached a piece of sheet metal with VHB tape to test it.

|

| Simple Linear Axis with all the components |

For testing, I taped a laser pointer to the carriage and pointed it at a cabinet 20ft (6.12m) away. My carriage is 75mm long and wide, so using Abbe error principles

$ \tan(\alpha) = \frac{\delta}{L} = \frac{g}{length of carriage} $

and

$\alpha = \arctan(\frac{\delta}{L})$

where if I want my bearing error to be max 0.159mm (error apportionment), I want my angular error to be

$\frac{0.159mm \times gap}{l} = 0.02deg$

and therefore max $\delta$ = 2.167 mm (repeatability at same location)

and max $\delta$ = 3.36mm (moving the carriage the full length of the 214mm-long rail)

|

| Laser target. The white paper is so I can draw on it, and the black tape spot is for the camera's benefit. |

Once I rotated the optical table to a reasonable target-width (video below), I was ready to start properly measure my linear axis.

It's possible to back-calculate the estimated angle of the assembly relative to the target based on the overall drift of the laser across all the trials, but I definitely won't conduct enough trials to properly statistics-away this particular source of error. Instead, I'll probably find a better calibration method for the next iteration of this linear axis once the actuator is attached.

Anyway, during testing I discovered that my clearance-bore + flat method did indeed have noticeable side-side error and worse than I calculated - 9.81mm, which was a 0.09deg angular error for repeatability testing. A lot of this is due to my setup itself not being squared up - angular error at the front was only 0.04deg of error compared to 0.14deg at the rear.

Traveling from back to front multiple times, I accrued an overall angular error of 0.23degrees. Womp. My estimation from looking at repeatability of the fronts and backs is that 0.05deg of that was due to the the table itself.

Given these results, I tried squaring up the optical table a bit better and put a 500g weight on the carriage to look at effects of adding a load. This time, my fronts and backs had more similar displacements - both errors were 0.1deg. However, sliding back and forth got an error of 0.5deg - twice as much as when I tried this with minimal loading, and 5x what my error spreadsheet budgeted for.

I suppose this is what I get for attaching my carriage to my bearings using compliant foam tape and attaching my laser with ducttape, and I'll find out how much better I can get when I add an actuator and reattach everything with more thought.

However, the real experimental error matched up with my scratchwork predictions, despite having a bore gap 0.2mm larger than intended (using 11/32" reamer instead of a 21/64"). So probably I shouldn't expect to achieve anything significantly better even with an actuator.